DIGITAL CREAMICS

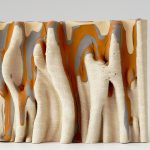

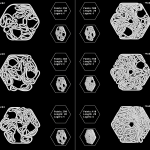

The students learned the theory and practice of additive processes in architecture in the course “Digital Ceramic”. In small projects, the software skills were developed to design for 3D printing as well as to generate the print files. In the next phase, individual projects of the students were elaborated and their own designs were printed in model scale.

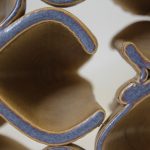

The focus here was on the material ceramic. Ceramics, i.e. fired clay, is already the most widely used building material on earth in the form of bricks. With the help of new technologies, this proven material can be rediscovered: Ceramics is a sustainable, natural material that is very durable when fired, fully recyclable and with relevant material properties in terms of thermal conductivity, chemical – and high temperature resistance, low conductivity, creates interesting products.

Technology allows us to produce novel, complex shapes and to develop our own design language for “Digital Ceramics”. In addition to geometric design possibilities, glaze was used as a design tool.The experiment was in translating traditional craft into digital craft, with a focus on materiality, sustainability, and digital design. With a focus on ceramics and 3D printing, we create a seamless interaction between material and machine, breaking down the boundaries between craft and digital design. After the semester, students will be able to plan, visualise, and prepare their own designs for fabrication using 3D printing. The scale of the designs ranges from furniture to facades to complete houses.

University of Innsbruck

department of architecture

exparch.hochbau

Studio: Marjan Colletti

Lecturer: Jan Contala, Philipp Schwaderer

student work